SAS Inno – Mas-i2 Inline Selective Solder

Our Inline Selective Solder System, the MAS-i2, offers users a way to accurately and efficiently solder through-hole components. The MAS-i2 effectively solders the back of any through-hole components which reduces the amount of solder used, making this system a much more efficient choice.

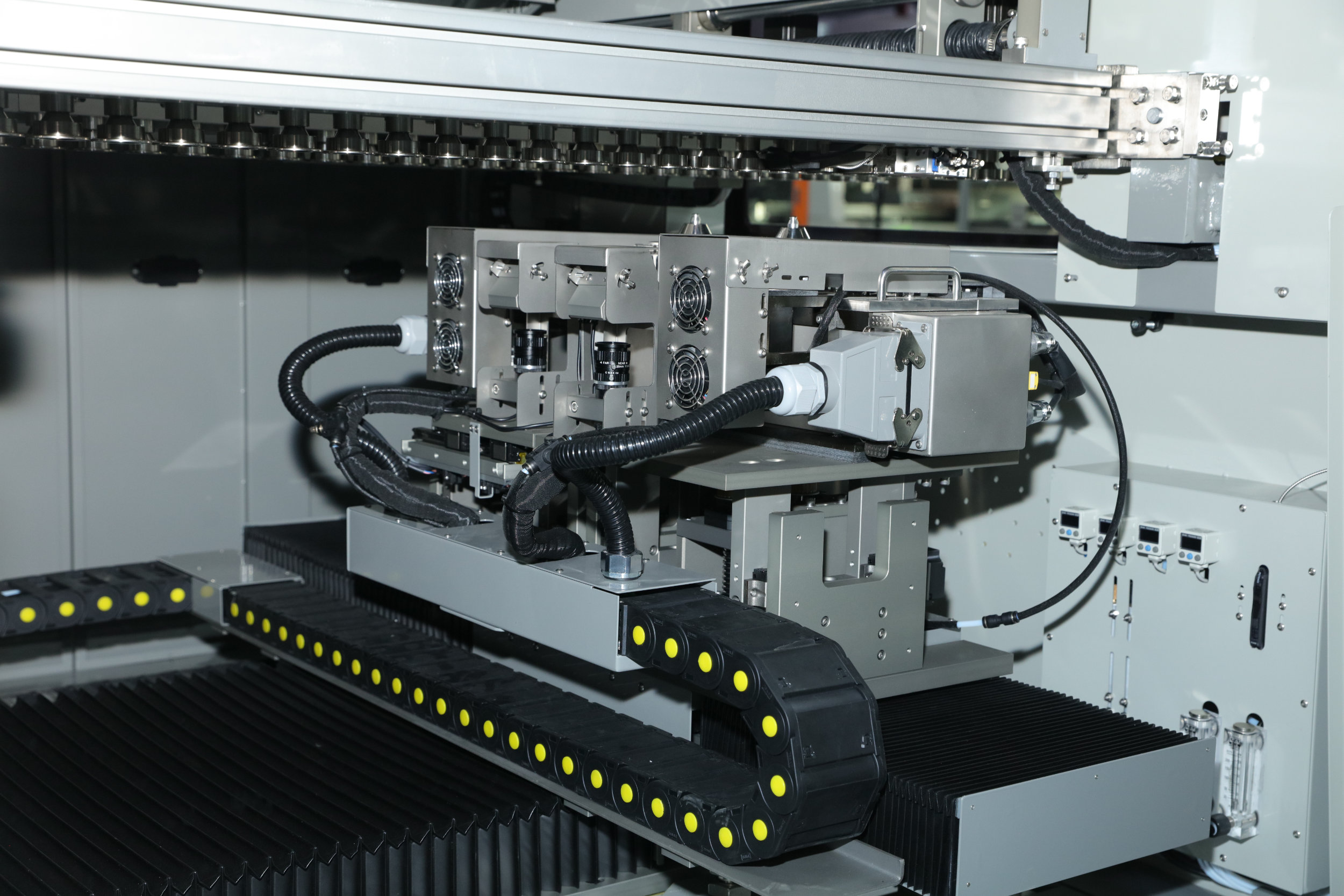

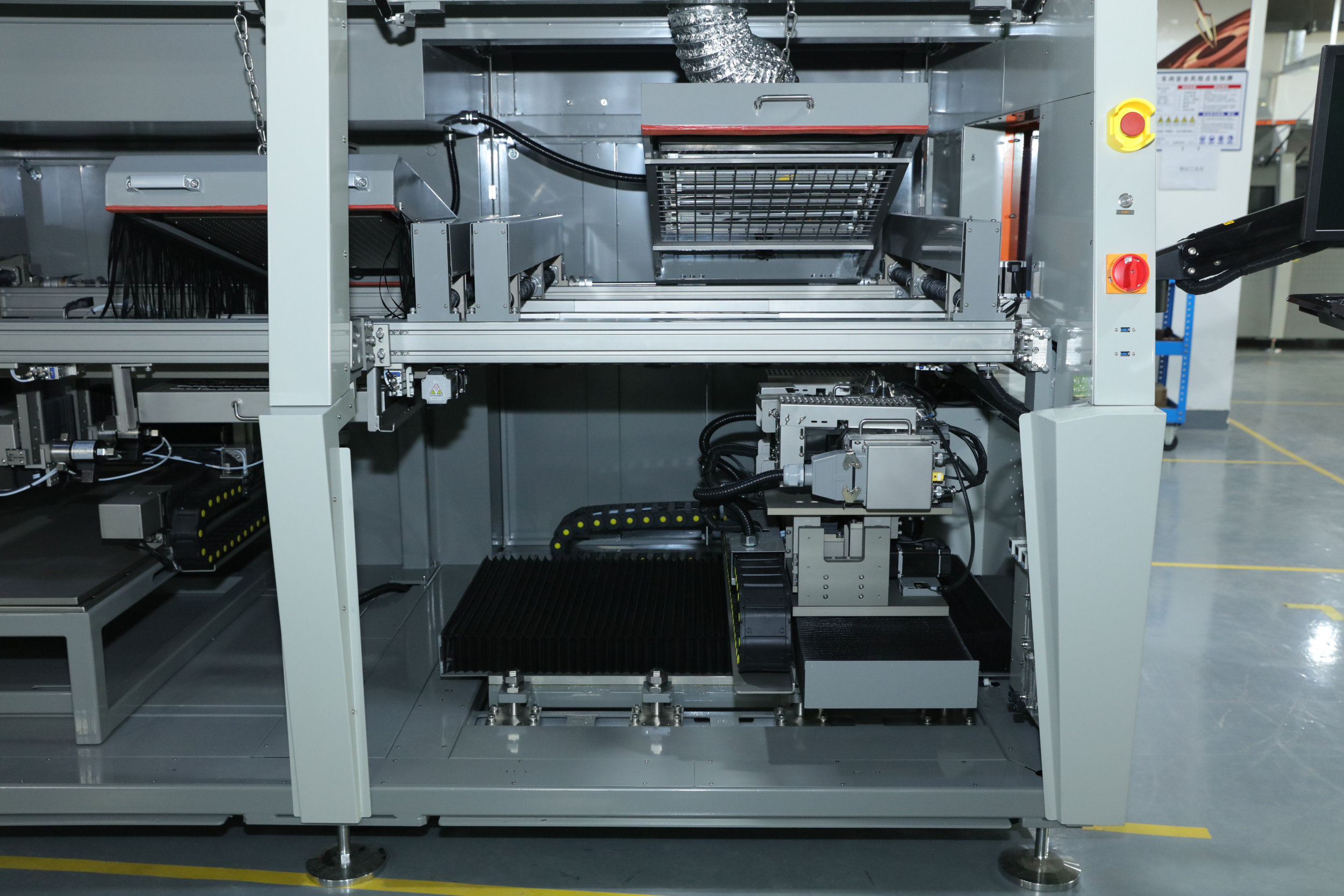

The inline version of the already efficient offline system offers a more automated solution for higher capacity board manufacturing and larger production lines. It features an X/Y servo table for fluxing, Z1 for drop jet flux with an optional Z2 for drop jet flux as well. This also comes with a controllable distance between each head from within the software. It uses a convection based preheating zone on the top and an IR based preheating zone on the bottom to allow for accurate temperature control of the board before the soldering process starts.

SAS Inno – Mas-i2 Inline Selective Solder

Our Inline Selective Solder System, the MAS-i2, offers users a way to accurately and efficiently solder through-hole components. The MAS-i2 effectively solders the back of any through-hole components which reduces the amount of solder used, making this system a much more efficient choice.

The inline version of the already efficient offline system offers a more automated solution for higher capacity board manufacturing and larger production lines. It features an X/Y servo table for fluxing, Z1 for drop jet flux with an optional Z2 for drop jet flux as well. This also comes with a controllable distance between each head from within the software. It uses a convection based preheating zone on the top and an IR based preheating zone on the bottom to allow for accurate temperature control of the board before the soldering process starts.

SAS Inno – Mas-i2

Inline Selective Solder

Our Inline Selective Solder System, the MAS-i2, offers users a way to accurately and efficiently solder through-hole components. The MAS-i2 effectively solders the back of any through-hole components which reduces the amount of solder used, making this system a much more efficient choice.

The inline version of the already efficient offline system offers a more automated solution for higher capacity board manufacturing and larger production lines. It features an X/Y servo table for fluxing, Z1 for drop jet flux with an optional Z2 for drop jet flux as well. This also comes with a controllable distance between each head from within the software. It uses a convection based preheating zone on the top and an IR based preheating zone on the bottom to allow for accurate temperature control of the board before the soldering process starts.

Features and Upgrades

Selective Soldering Pot

The soldering pot is made from titanium making it 100% capable of lead free application and as standard it is fitted with a mechanical pump for easy maintenance. The soldering head also comes equipped as standard with the N2 direct heating system to enhance the wetting ability for lead free soldering.

Wet Solder Nozzles

Supplied with the machine are five different sized wet soldering nozzles to allow for universal applications to almost all customers. However it is also possible for these solder nozzles to be designed specifically to meet the requirements for a unique application if required.

Live Soldering Inspection

The MAS-i2 comes standard with an additional monitor which can be used to provide a live feed directly from the soldering tip to allow the operator to view soldering process in real time without needing to open the machine door.

Features and Upgrades

Selective Soldering Pot

The soldering pot is made from titanium making it 100% capable of lead free application and as standard it is fitted with a mechanical pump for easy maintenance. The soldering head also comes equipped as standard with the N2 direct heating system to enhance the wetting ability for lead free soldering.

Wet Solder Nozzles

Supplied with the machine are five different sized wet soldering nozzles to allow for universal applications to almost all customers. However it is also possible for these solder nozzles to be designed specifically to meet the requirements for a unique application if required.

Live Soldering Inspection

The MAS-i2 comes standard with an additional monitor which can be used to provide a live feed directly from the soldering tip to allow the operator to view soldering process in real time without needing to open the machine door.

Features and Upgrades

Selective Soldering Pot

The soldering pot is made from titanium making it 100% capable of lead free application and as standard it is fitted with a mechanical pump for easy maintenance. The soldering head also comes equipped as standard with the N2 direct heating system to enhance the wetting ability for lead free soldering.

Wet Solder Nozzles

Supplied with the machine are five different sized wet soldering nozzles to allow for universal applications to almost all customers. However it is also possible for these solder nozzles to be designed specifically to meet the requirements for a unique application if required.

Live Soldering Inspection

The MAS-i2 comes standard with an additional monitor which can be used to provide a live feed directly from the soldering tip to allow the operator to view soldering process in real time without needing to open the machine door.

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com