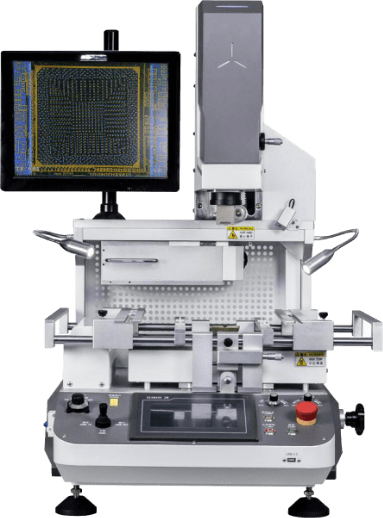

Seamark – BGA Rework Station

The Seamark ZM-R7220A BGA Rework Station features a large area of infrared carbon fibre pre-heating system, with the advantage of ensuring that the component is heated quickly and evenly while maintaining zero ligh pollution. The temperature parameters can be defined and protected by administrators to prevent errors within the configuration. The machine utilises a ten segment temperature control process making it suitable for all kinds of BGA rework while allowing for an unlimited amount of stored temperature profiles where you can simply press one key to load the profile.

Three K-Type sensors are available to allow for high precision temperature testing at point required on either the PCB or BGA and then the PC can generate a report of the analysis automatically. The Rework Station also allows for automatic desoldering and soldering without the need for manual adjustment. The hot air flow can be adjusted to meet the requirements of any chip and the bottom hot air lifting control is available in the front panel making it adjustable at any time. Optionally this machine can also come with laser positioning to make positioning faster.

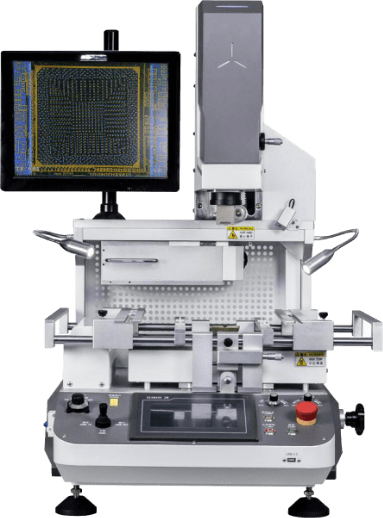

Seamark – BGA Rework Station

The Seamark ZM-R7220A BGA Rework Station features a large area of infrared carbon fibre pre-heating system, with the advantage of ensuring that the component is heated quickly and evenly while maintaining zero ligh pollution. The temperature parameters can be defined and protected by administrators to prevent errors within the configuration. The machine utilises a ten segment temperature control process making it suitable for all kinds of BGA rework while allowing for an unlimited amount of stored temperature profiles where you can simply press one key to load the profile.

Three K-Type sensors are available to allow for high precision temperature testing at point required on either the PCB or BGA and then the PC can generate a report of the analysis automatically. The Rework Station also allows for automatic desoldering and soldering without the need for manual adjustment. The hot air flow can be adjusted to meet the requirements of any chip and the bottom hot air lifting control is available in the front panel making it adjustable at any time. Optionally this machine can also come with laser positioning to make positioning faster.

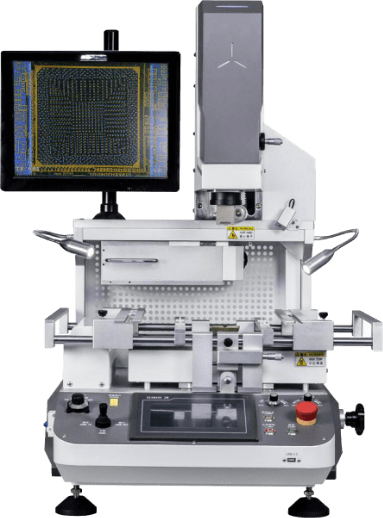

Seamark – BGA Rework Station

The Seamark ZM-R7220A BGA Rework Station features a large area of infrared carbon fibre pre-heating system, with the advantage of ensuring that the component is heated quickly and evenly while maintaining zero ligh pollution. The temperature parameters can be defined and protected by administrators to prevent errors within the configuration. The machine utilises a ten segment temperature control process making it suitable for all kinds of BGA rework while allowing for an unlimited amount of stored temperature profiles where you can simply press one key to load the profile.

Three K-Type sensors are available to allow for high precision temperature testing at point required on either the PCB or BGA and then the PC can generate a report of the analysis automatically. The Rework Station also allows for automatic desoldering and soldering without the need for manual adjustment. The hot air flow can be adjusted to meet the requirements of any chip and the bottom hot air lifting control is available in the front panel making it adjustable at any time. Optionally this machine can also come with laser positioning to make positioning faster.

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com