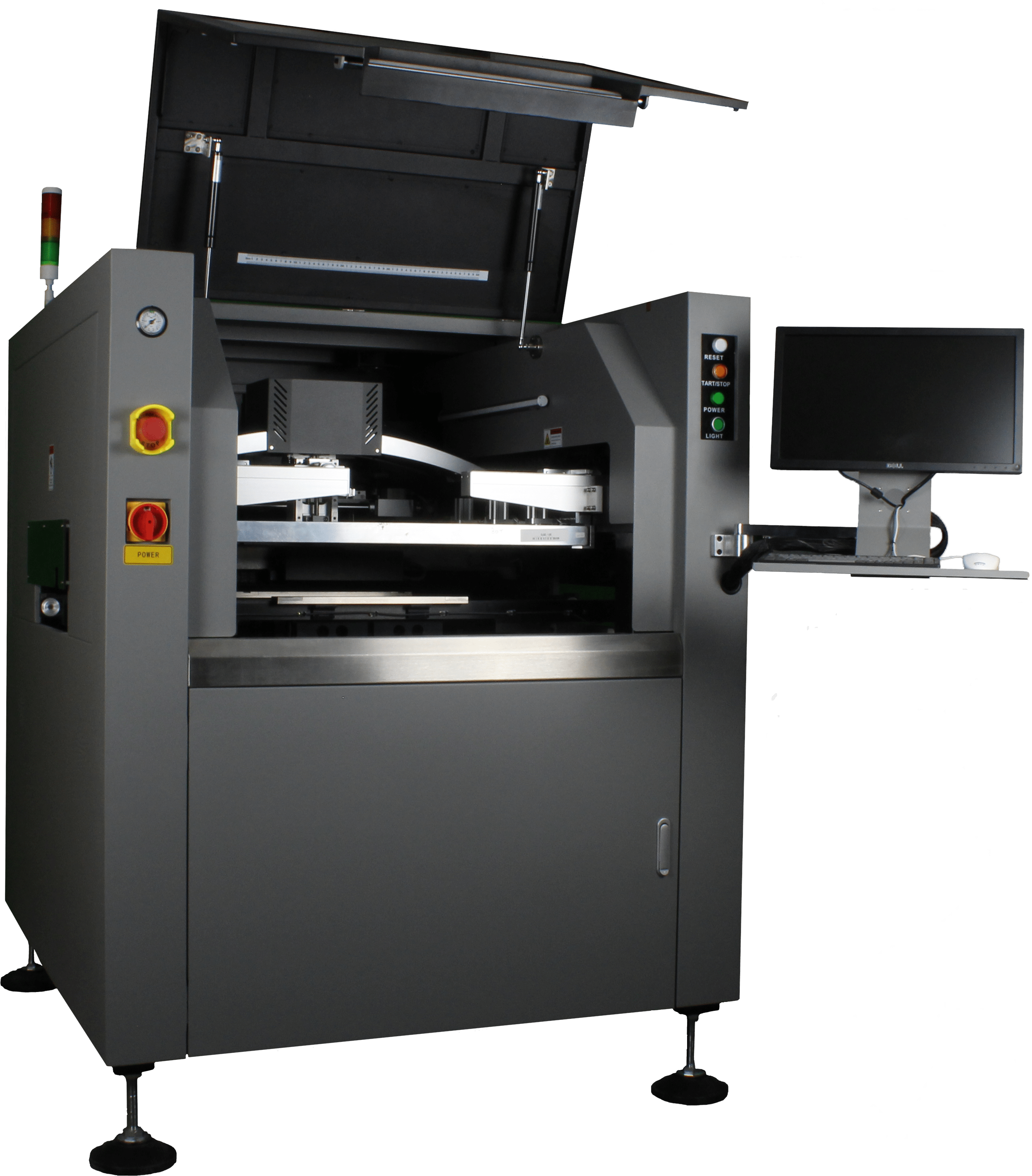

Prey By Detech – Hawk

Vision Screen Printer

Our fully Automatic Hawk Screen Printer features an automatic machine vision recognition system, using a high-precision Servo drive system to achieve fast and accurate alignment. This makes the machine capable of reaching +/- 0.01mm. It features a unique and independent cleaning system, where the cycle time is less than seven seconds to ensure high printing quality and reduced downtime for cleaning.

The vision system uses a fiducious camera which is used to make sure that the stencil and PCB are precisely aligned to avoid any issues with the final printing result. The machine also features a programmable printing head which is designed to meet the needs of different users that require different pressures on the front and rear squeegees. This can be used to prevent solder paste leakage and provide a stable levelling of the squeegees for precise solder paste transfer.

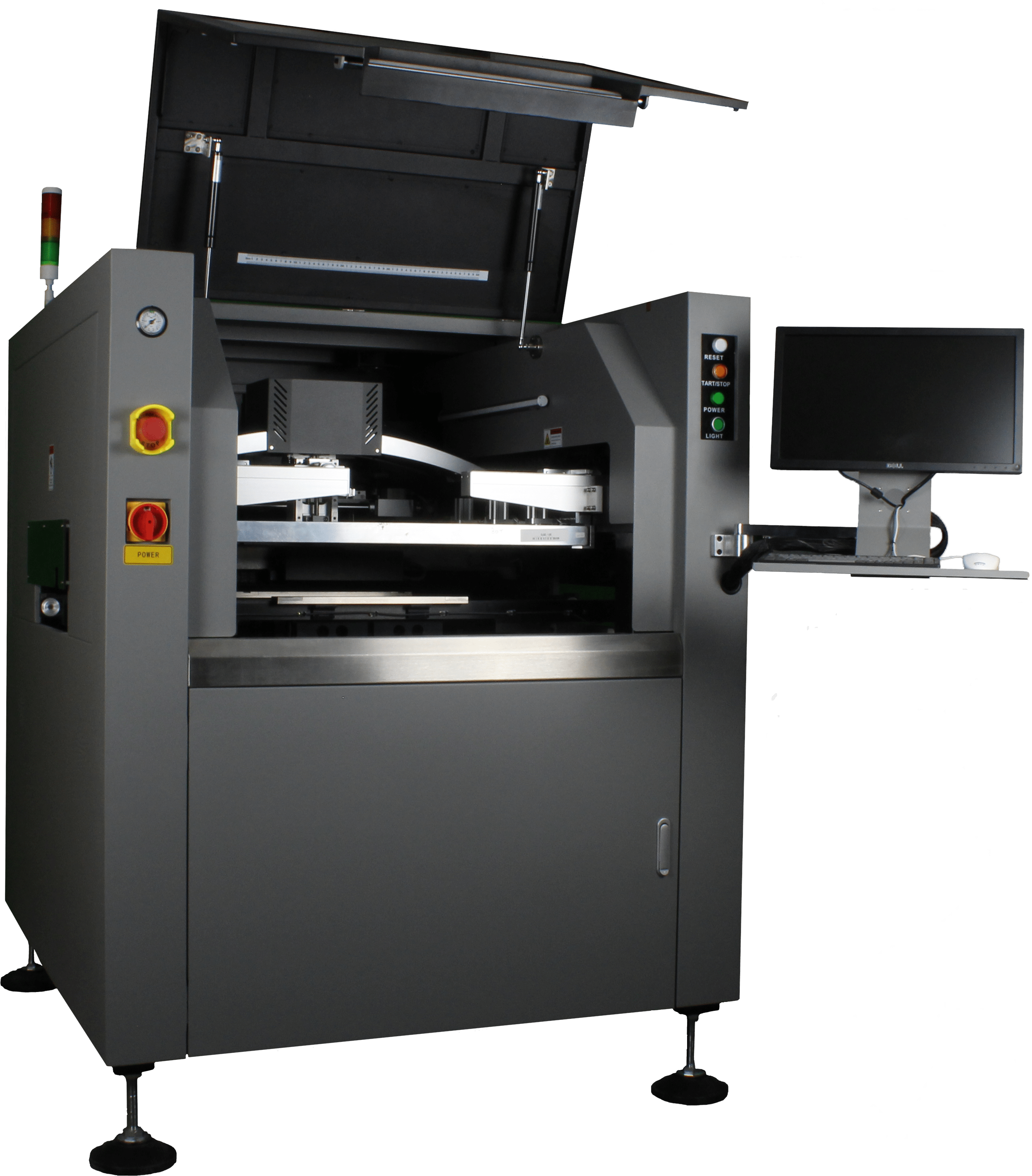

Prey By Detech – Hawk

Vision Screen Printer

Our fully Automatic Hawk Screen Printer features an automatic machine vision recognition system, using a high-precision Servo drive system to achieve fast and accurate alignment. This makes the machine capable of reaching +/- 0.01mm. It features a unique and independent cleaning system, where the cycle time is less than seven seconds to ensure high printing quality and reduced downtime for cleaning.

The vision system uses a fiducious camera which is used to make sure that the stencil and PCB are precisely aligned to avoid any issues with the final printing result. The machine also features a programmable printing head which is designed to meet the needs of different users that require different pressures on the front and rear squeegees. This can be used to prevent solder paste leakage and provide a stable levelling of the squeegees for precise solder paste transfer.

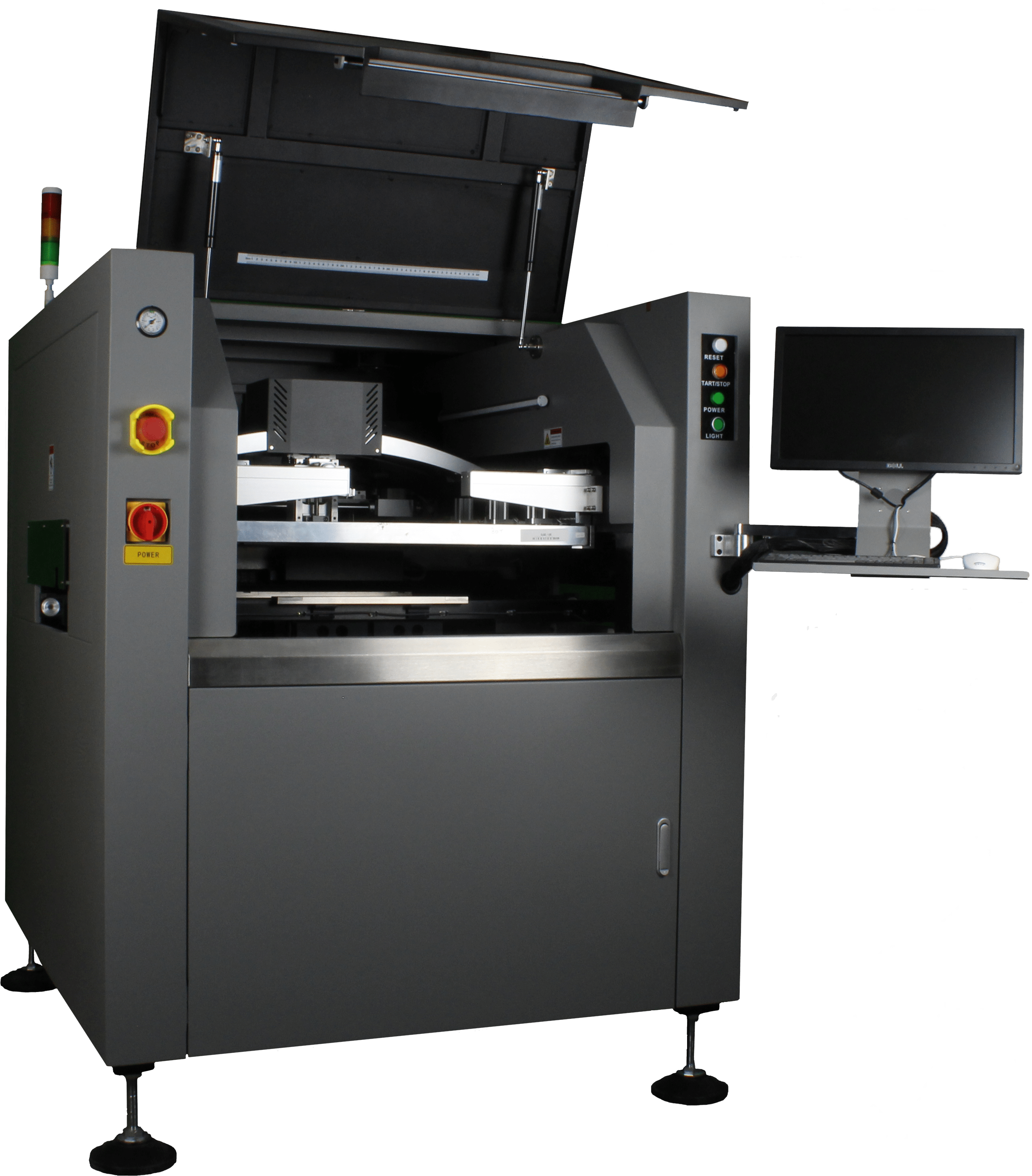

Prey By Detech – Hawk

Vision Screen Printer

Our fully Automatic Hawk Screen Printer features an automatic machine vision recognition system, using a high-precision Servo drive system to achieve fast and accurate alignment. This makes the machine capable of reaching +/- 0.01mm. It features a unique and independent cleaning system, where the cycle time is less than seven seconds to ensure high printing quality and reduced downtime for cleaning.

The vision system uses a fiducious camera which is used to make sure that the stencil and PCB are precisely aligned to avoid any issues with the final printing result. The machine also features a programmable printing head which is designed to meet the needs of different users that require different pressures on the front and rear squeegees. This can be used to prevent solder paste leakage and provide a stable levelling of the squeegees for precise solder paste transfer.

Features and Upgrades

Stencil Cleaning System

The stencil cleaning system includes 3 cleaning types, dry, wet and vacuum. These three modes can be individually selected or combined for different use cases. The system allows manual cleaning within its operation menu which shortens the cleaning time and improves production efficiency.

Programmable Print Head

The print head is designed to meet the needs of different pressures at the front and rear squeegee and the require of the squeegee’s levelling stability, to prevent solder paste leakage and squeegee blades with flexible clamping. Each squeegee’s pressure can be independently programmed, this provides a stable levelling of the squeegees for a precise solder paste transfer.

Standard 2D Inspection

Fully included with the Hawk Screen Printer from 2021 there is now a 2D Inspection module built into the software, this allows for the checking of the paste definition of print to alert you to any misprints that could be caused by low solder deposits due to a lack of solder on the stencil as well as blocked apertures.

Features and Upgrades

Stencil Cleaning System

The stencil cleaning system includes 3 cleaning types, dry, wet and vacuum. These three modes can be individually selected or combined for different use cases. The system allows manual cleaning within its operation menu which shortens the cleaning time and improves production efficiency.

Programmable Print Head

The print head is designed to meet the needs of different pressures at the front and rear squeegee and the require of the squeegee’s levelling stability, to prevent solder paste leakage and squeegee blades with flexible clamping. Each squeegee’s pressure can be independently programmed, this provides a stable levelling of the squeegees for a precise solder paste transfer.

Standard 2D Inspection

Fully included with the Hawk Screen Printer from 2021 there is now a 2D Inspection module built into the software, this allows for the checking of the paste definition of print to alert you to any misprints that could be caused by low solder deposits due to a lack of solder on the stencil as well as blocked apertures.

Features and Upgrades

Stencil Cleaning System

The stencil cleaning system includes 3 cleaning types, dry, wet and vacuum. These three modes can be individually selected or combined for different use cases. The system allows manual cleaning within its operation menu which shortens the cleaning time and improves production efficiency.

Programmable Print Head

The print head is designed to meet the needs of different pressures at the front and rear squeegee and the require of the squeegee’s levelling stability, to prevent solder paste leakage and squeegee blades with flexible clamping. Each squeegee’s pressure can be independently programmed, this provides a stable levelling of the squeegees for a precise solder paste transfer.

Standard 2D Inspection

Fully included with the Hawk Screen Printer from 2021 there is now a 2D Inspection module built into the software, this allows for the checking of the paste definition of print to alert you to any misprints that could be caused by low solder deposits due to a lack of solder on the stencil as well as blocked apertures.

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com