Prey By Detech- Power Oven Series

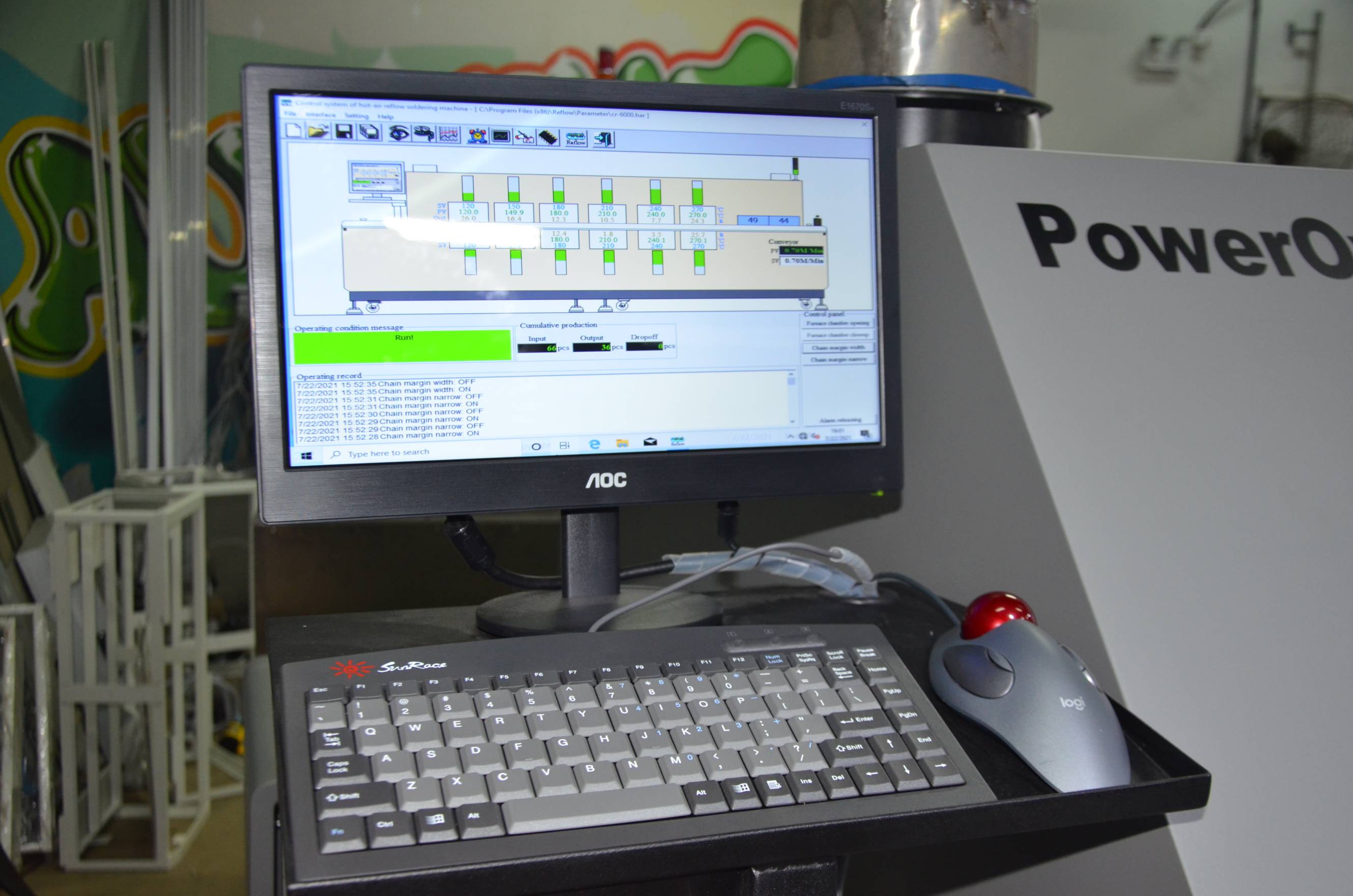

The Lead Free Power Oven Reflow Series is a compact inline small footprint soldering solution. The PowerOven-6 features six upper heating zones and six lower heating zones which provide a full forced hot air convection system with individual temperature controlled zones. The system uses a touchscreen and PLC control system which can hold up to 50 different profiles offering flexible & quick changing of profiles. The control system is also equipped with two thermocouple ports so that thermocouples can be connected to test and quick test the oven profile.

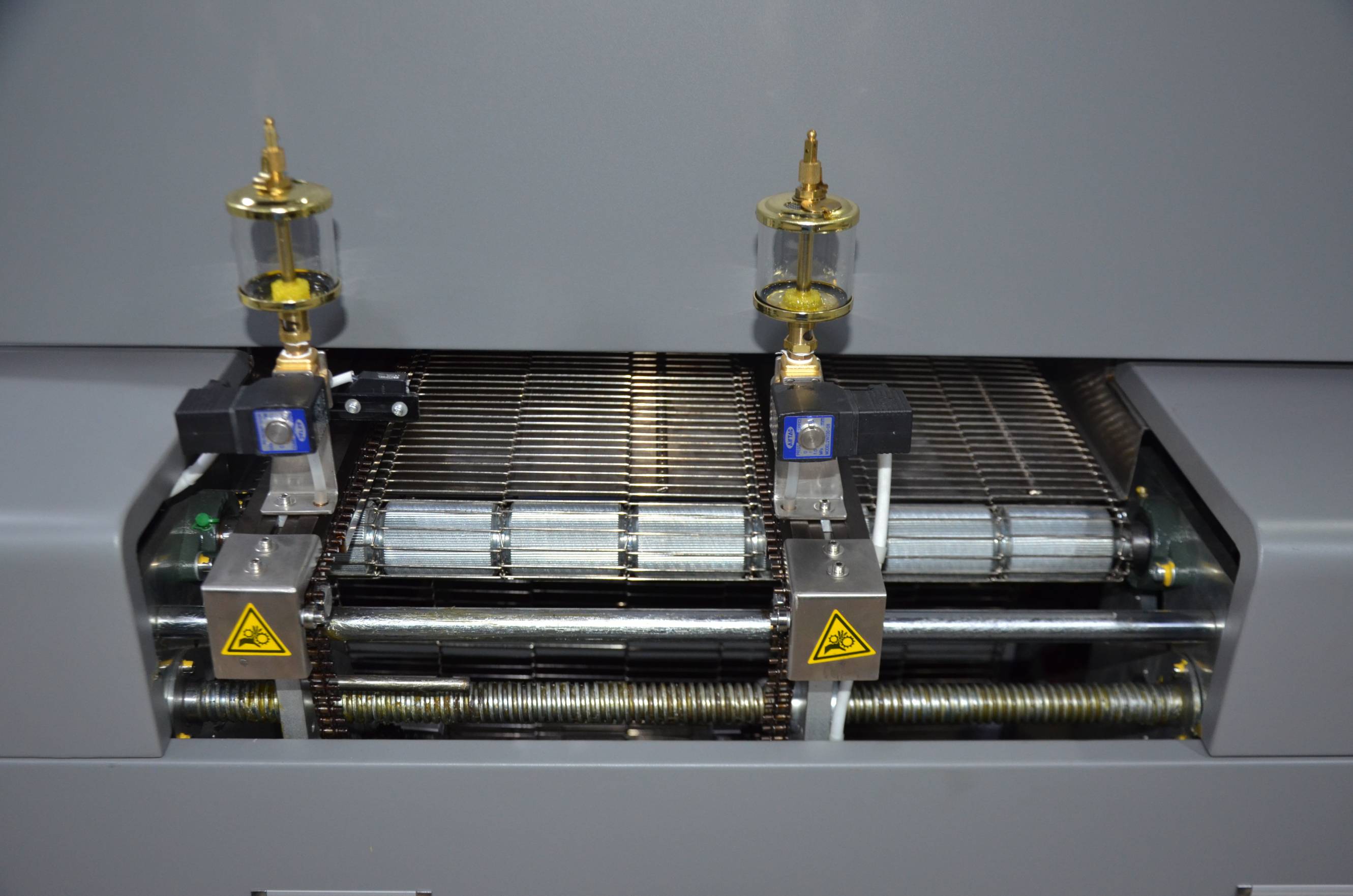

The conveyor system combines a 330mm mesh belt combined with a 300mm pin conveyor for full inline reflow capability. The machine can be provided in either single of 3 phase configurations and is built to be fully smema ready with sensors and adjustable height levels. Each of the PowerOven models also come with 3 different start up profiles to allow for low power start up. With a heated tunnel length in excess of 1500mm combined with adjustable belt speed control allows for great flexibility for such a small footprint system.

The PowerOven Series, like all Prey products, is backed by UK based spare parts and is fully CE Certified.

Prey By Detech- Power Oven Series

The Lead Free Power Oven Reflow Series is a compact inline small footprint soldering solution. The PowerOven-6 features six upper heating zones and six lower heating zones which provide a full forced hot air convection system with individual temperature controlled zones. The system uses a touchscreen and PLC control system which can hold up to 50 different profiles offering flexible & quick changing of profiles. The control system is also equipped with two thermocouple ports so that thermocouples can be connected to test and quick test the oven profile.

The conveyor system combines a 330mm mesh belt combined with a 300mm pin conveyor for full inline reflow capability. The machine can be provided in either single of 3 phase configurations and is built to be fully smema ready with sensors and adjustable height levels. Each of the PowerOven models also come with 3 different start up profiles to allow for low power start up. With a heated tunnel length in excess of 1500mm combined with adjustable belt speed control allows for great flexibility for such a small footprint system.

The PowerOven Series, like all Prey products, is backed by UK based spare parts and is fully CE Certified.

Prey By Detech- Power Oven Series

Reflow Oven Series

The Lead Free Power Oven Reflow Series is a compact inline small footprint soldering solution. The PowerOven-6 features six upper heating zones and six lower heating zones which provide a full forced hot air convection system with individual temperature controlled zones. The system uses a touchscreen and PLC control system which can hold up to 50 different profiles offering flexible & quick changing of profiles. The control system is also equipped with two thermocouple ports so that thermocouples can be connected to test and quick test the oven profile.

The conveyor system combines a 330mm mesh belt combined with a 300mm pin conveyor for full inline reflow capability. The machine can be provided in either single of 3 phase configurations and is built to be fully smema ready with sensors and adjustable height levels. Each of the PowerOven models also come with 3 different start up profiles to allow for low power start up. With a heated tunnel length in excess of 1500mm combined with adjustable belt speed control allows for great flexibility for such a small footprint system.

The PowerOven Series, like all Prey products, is backed by UK based spare parts and is fully CE Certified.

Features and Upgrades

Nitrogen Atmosphere Compatible Models

All of our reflow oven models are available in both a standard configuration and a nitrogen compatible configuration for those clients who want the flexibility of soldering in both environments. It is widely agreed that oxygen reduction through inert gas introduction (Usually N2) allows for a wider process window and better solder joints through a reduction of oxidation.

Precise Upper and Lower Temperature Controls

Each of the models from our PowerOven series feature independent and precise temperature profiling with an accuracy of +/- 1°C. With the addition of the high-speed blower motors installed adjacent to each heat source for maximum convection, you’re guaranteed a ΔT of +/-2°C across the PCB assembly. This diffuser design provides you with low-velocity, low-turbulence air flow that prevents component shifts or disturbances.

Pin-Over-Mesh Conveyor

Our PowerOven range of reflow ovens can meet virtually any product or production requirement with its standard adjustable-rail, pin type conveyor. These ovens can handle PCBs up to 450mm installed over a 570mm stainless-steel mesh belt. With double-sided and inline processing capabilities, this belt is ideal for fast changeovers.

Features and Upgrades

Nitrogen Atmosphere Compatible Models

All of our reflow oven models are available in both a standard configuration and a nitrogen compatible configuration for those clients who want the flexibility of soldering in both environments. It is widely agreed that oxygen reduction through inert gas introduction (Usually N2) allows for a wider process window and better solder joints through a reduction of oxidation.

Precise Upper and Lower Temperature Controls

Each of the models from our PowerOven series feature independent and precise temperature profiling with an accuracy of +/- 1°C. With the addition of the high-speed blower motors installed adjacent to each heat source for maximum convection, you’re guaranteed a ΔT of +/-2°C across the PCB assembly. This diffuser design provides you with low-velocity, low-turbulence air flow that prevents component shifts or disturbances.

Pin-Over-Mesh Conveyor

Our PowerOven range of reflow ovens can meet virtually any product or production requirement with its standard adjustable-rail, pin type conveyor. These ovens can handle PCBs up to 450mm installed over a 570mm stainless-steel mesh belt. With double-sided and inline processing capabilities, this belt is ideal for fast changeovers.

Features and Upgrades

Nitrogen Atmosphere Compatible Models

All of our reflow oven models are available in both a standard configuration and a nitrogen compatible configuration for those clients who want the flexibility of soldering in both environments. It is widely agreed that oxygen reduction through inert gas introduction (Usually N2) allows for a wider process window and better solder joints through a reduction of oxidation.

Precise Upper and Lower Temperature Controls

Each of the models from our PowerOven series feature independent and precise temperature profiling with an accuracy of +/- 1°C. With the addition of the high-speed blower motors installed adjacent to each heat source for maximum convection, you’re guaranteed a ΔT of +/-2°C across the PCB assembly. This diffuser design provides you with low-velocity, low-turbulence air flow that prevents component shifts or disturbances.

Pin-Over-Mesh Conveyor

Our PowerOven range of reflow ovens can meet virtually any product or production requirement with its standard adjustable-rail, pin type conveyor. These ovens can handle PCBs up to 450mm installed over a 570mm stainless-steel mesh belt. With double-sided and inline processing capabilities, this belt is ideal for fast changeovers.

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com

Contact Us

Detech Europe Limited

The Farm Office, Model Farm,

Atwick Road, Bewholme,

East Riding of Yorkshire,

YO25 8DT, United Kingdom

Phone: +44 (0)1262 409944

Email: sales@detech-europe.com